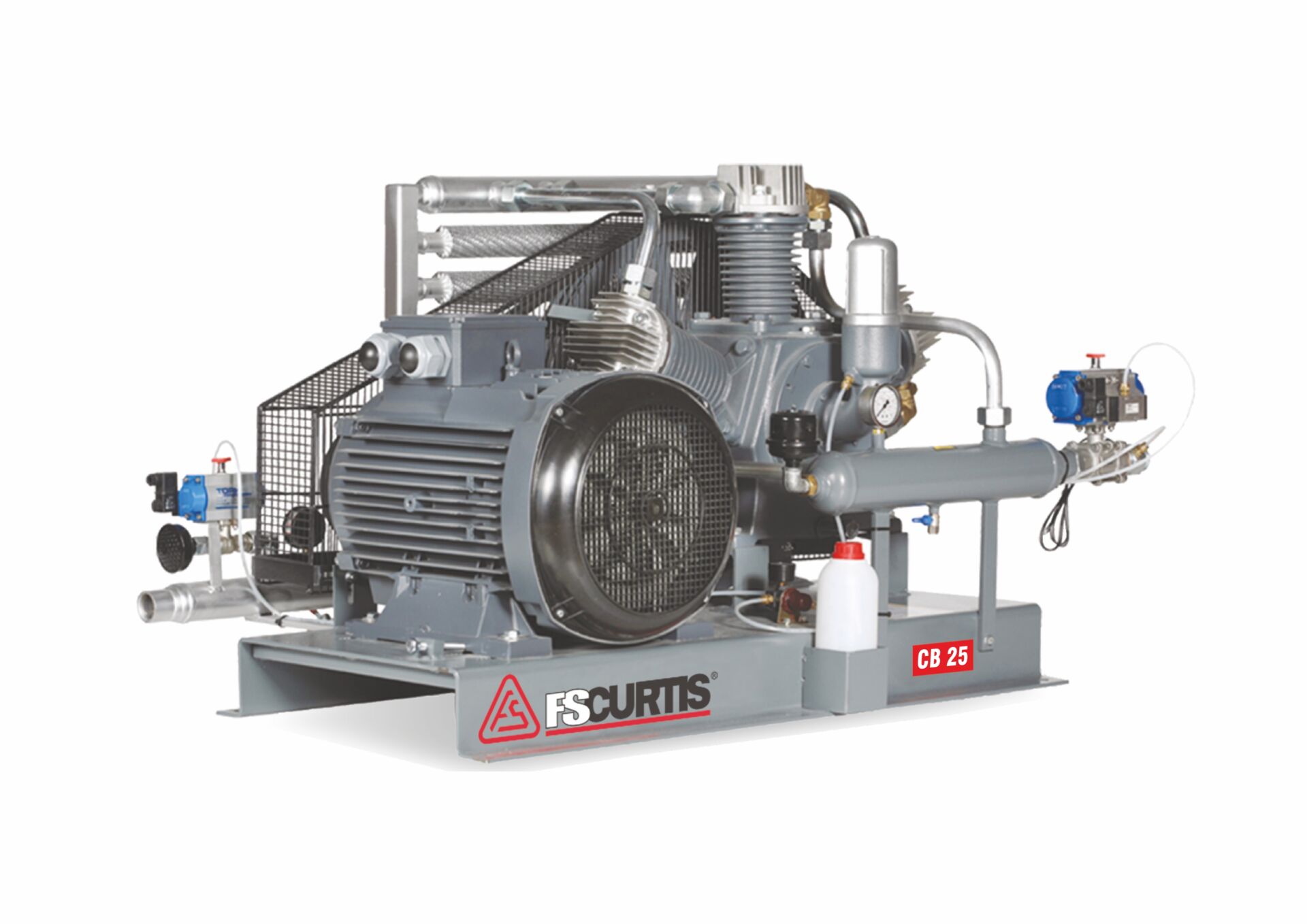

40 Bar, Oil-Lubricated, Booster Compressor Compressed air is an energy source that is as important as electricity and hydraulics. Especially for the production of pet bottles, which are being used more and more in daily life, by people all over the world. Besides, the applications such as leak tests of hydraulic and pneumatic devices, specific drive cylinders, presses, and fixture apparatus also need high-pressure air. Unlike other applications requiring only low-pressure air, both low and high-pressure levels of air up to 40 bars ought to be used in the facilities for these applications. Therefore, instead of designing the whole system considering the high-pressure need, increasing the air pressure just at the certain points where high pressure is needed, is the most energy and cost-efficient solution. As a manufacturer having reciprocating booster compressors in its product portfolio which boost the 7-13 bar compressed air taken from rotary screw compressors, up to 40 bars, FS-Curtis provides the most appropriate solutions with its years of experience and quality policy to pet manufacturers and the enterprises which have to use high-pressure air. These compressors can also be modified to serve as boosters for nitrogen.

Send Message