Air Compressor Installation Services

At PPI Engineers, we specialize in providing expert air compressor installation services tailored to your specific needs. Whether you're setting up a new system for your industrial facility or upgrading your existing one, our team is here to ensure your air compressor is installed safely, efficiently, and professionally.

Our Air Compressor Installation Services Include:

Site Assessment and Consultation

Our technicians will conduct a thorough assessment of your space to determine the best location for your air compressor. We’ll consider factors such as airflow, power supply, and accessibility to ensure the system operates optimally.

Custom Installation Solutions

We offer installation for a wide range of air compressor types, including rotary screw compressors, reciprocating compressors, and centrifugal compressors. Whether you need a small unit for a workshop or a large system for a manufacturing facility, we have the experience to meet your requirements.

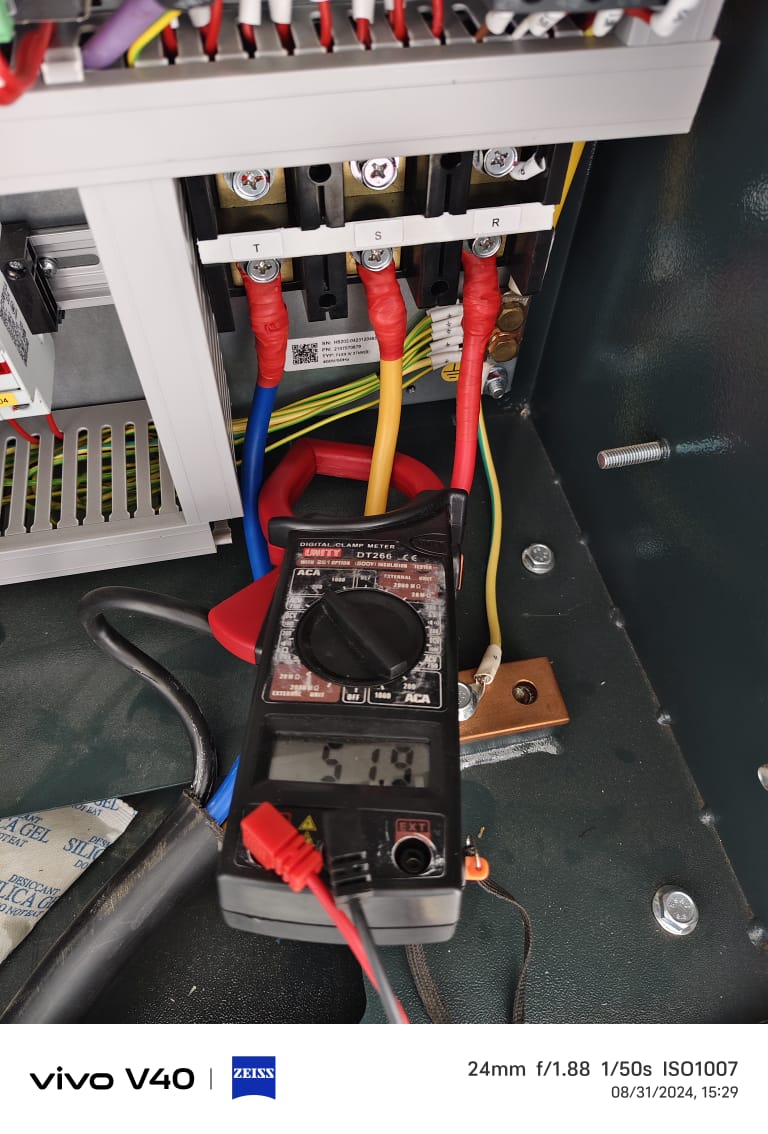

Electrical and Piping Installation

We install all necessary electrical connections and piping systems to ensure your air compressor runs smoothly. Our team ensures that your system is compliant with all local codes and standards for safety and efficiency.

Vibration and Noise Control

Air compressors can generate vibration and noise, which may affect your environment. We implement soundproofing and vibration reduction measures to minimize disturbances and improve system longevity.

System Integration

If you’re adding an air compressor to an existing system, we’ll integrate it seamlessly with your current infrastructure. This ensures optimized performance, energy efficiency, and reduced downtime.

Post-Installation Support and Maintenance

Our service doesn’t end with installation. We offer ongoing maintenance and support to ensure that your air compressor continues to operate at peak efficiency. Regular servicing will help extend the lifespan of your equipment and reduce the likelihood of costly repairs.

Why Choose Us for Your Air Compressor Installation?

Experienced Technicians: Our team is trained and experienced in installing air compressors of all types and sizes, ensuring the job is done right the first time.

Comprehensive Service: From site assessment and installation to maintenance and repair, we provide a full suite of air compressor services.

Energy Efficiency: We focus on delivering energy-efficient solutions that can reduce operational costs and improve overall productivity.

Safety and Compliance: We adhere to the highest safety standards, ensuring that all installations meet industry regulations and safety codes.

Customer Satisfaction: We pride ourselves on delivering excellent customer service, with clear communication and professional results that meet your expectations.

Send Message