Air Compressor Repair Services

An Annual Maintenance Contract (AMC) for air compressors is a service agreement between a company and a service provider to ensure the proper functioning, efficiency, and longevity of the air compressors over a defined period—usually one year. This type of contract guarantees that the compressors are serviced regularly, undergo preventive maintenance, and are repaired promptly in case of breakdowns.

Here’s an outline of what an AMC for air compressors typically includes:

1. Scope of AMC for Air Compressors

Preventive Maintenance: Regular checks to ensure the compressor is operating at optimal performance. This includes oil changes, filter replacements, belt checks, and more.

Emergency Repairs: Covering breakdowns, and ensuring that the compressor is repaired quickly to minimize downtime.

Lubrication and Inspection: Regular lubrication of moving parts to avoid wear and tear and thorough inspection of key components like motors, valves, and hoses.

Diagnostics: Periodic diagnostics to identify potential problems before they lead to costly repairs.

Replacement of Parts: If certain parts are covered under the contract, they are replaced or serviced when necessary.

Operational Efficiency Checks: Monitoring efficiency to ensure the air compressor is functioning without consuming excessive power.

2. Types of AMCs

Comprehensive AMC: Covers all parts and labor costs for both preventive maintenance and repairs. This is an all-inclusive package.

Non-Comprehensive AMC: Only includes the cost of maintenance services (labor and services) but may exclude the cost of parts. In this case, spare parts would be billed separately.

3. Benefits of an AMC for Air Compressors

Reduced Downtime: Regular maintenance helps prevent unexpected breakdowns, ensuring the compressor runs smoothly and reducing downtime.

Cost-Effective: AMCs can be more economical compared to paying for individual repairs or replacements when things go wrong.

Prolonged Equipment Life: Regular maintenance keeps the equipment in top condition, extending its useful life.

Energy Savings: Properly maintained compressors run more efficiently, reducing energy costs.

Priority Service: AMCs often come with the benefit of priority service in case of breakdowns, minimizing wait times.

4. Key Components of an AMC Agreement

Service Frequency: How often the compressor will be serviced (e.g., quarterly, bi-annually, etc.).

Response Time: The expected response time for attending to issues or breakdowns.

Replacement of Parts: What parts will be replaced under the contract, and which will require separate payment.

Labour Charges: Whether the AMC includes labor charges or if they are billed separately.

Duration of the Contract: Typically, AMCs are offered for 1 year but can be extended depending on the requirements.

Performance Standards: Specific performance benchmarks the compressor must meet, ensuring it operates efficiently.

5. Air Compressor Maintenance Checklist

Checking Air Intake Filter: Replacing or cleaning air filters regularly to ensure efficient air intake.

Oil Check: Checking oil levels and changing the oil as per manufacturer guidelines.

Tightening of Belts and Hoses: Ensuring there are no leaks and that belts are in good condition.

Cooling System Check: Inspecting the cooling system to prevent overheating.

Air-end Inspection: Checking for internal wear and tear, which may require cleaning, lubrication, or even part replacement.

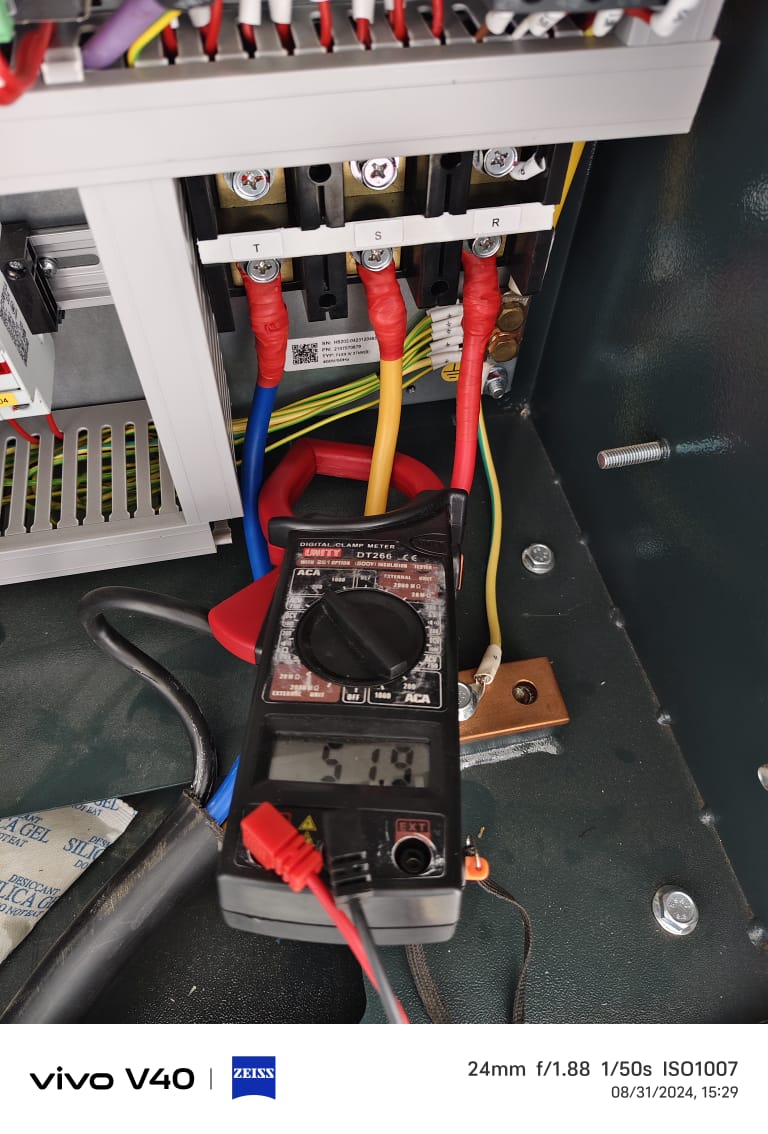

Electrical Inspection: Ensuring all electrical components are working properly and that connections are secure.

6. How to Choose the Right AMC for Your Air Compressor

Compatibility with Compressor Model: Ensure the service provider specializes in your brand and type of air compressor.

Reputation of the Service Provider: Choose a reliable service provider with a proven track record in air compressor maintenance.

Cost and Coverage: Compare different service packages to ensure you are getting the best value for the services provided.

Response Time and Service Availability: Ensure the service provider can attend to urgent issues promptly.

Send Message